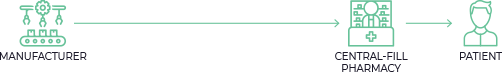

RxE2 dispensing service , for the first time, moves the packaging and labeling of investigational drugs from a product-centric to a patient-centric model. In this new model, drug supplies are dispensed to patients by a pharmacist from a central pharmacy. In addition to Good Manufacturing Practice requirements, investigational drugs are packaged and labeled according to the requirements and regulations of the practice of pharmacy.

Simple, Effective, Cost-Efficient

Our dispensing eliminates unnecessary and redundant steps, delivering a simple, more efficient clinical supply chain. Clinical supplies are labeled and dispensed with a familiar, patient-friendly pharmacy prescription label, improving the quality of compliance and adherence.

Our dispensing reduces packaging, labeling, distribution, and storage costs, and the simplified process reduces the project manager’s burden for planning, forecasting, and implementation.

Current Process

RxE2 Dispensing Process

Regulations

Do you know how state pharmacy regulations apply to investigational drugs and why clinical trials need a central pharmacy?

Read our white paper to find out.

Time, Cost, & Quality

RxE2 Dispensing eliminates costs associated with unnecessary planning, packaging, and labeling of clinical supplies.

Our most current pricing shows as much as a 50% cost savings.

Why Pharmacists

Utilizing Trusted Medication Experts

Today’s pharmacies are untapped resources. Based on trust and one-on-one patient care, pharmacists build life-long relationships with their patients. RxE2 understands the importance of these relationships and the vital role of the pharmacist in dispensing, compliance, adherence, and retention. The practice of pharmacy is the cornerstone of RxE2’s dispensing services.

Time, Cost, and Quality

RxE2 dispensing redefines how we think about time, cost, and quality of the clinical supply chain model

Time

Much of what clinical supply project managers do for the traditional clinical supplies packaging and labeling process focuses on making the GMP process work for individual protocols while maintaining blind dispensing for patients at clinical sites. Whole departments have been created to ensure the success of this planning process. Additionally, large Good Manufacturing Practices (GMP) manufacturing facilities are dedicated to clinical supplies packaging and labeling to meet those clinical protocol requirements. It takes time to plan, manufacture, and distribute clinical supplies to patients.

Our dispensing eliminates most of the time needed for project management, specialized packaging and labeling operations, and for supply distribution to patients. All of this can be accomplished by incorporating the practice of pharmacy into clinical research.

RxE2 dispensing requires shipping open-label, bulk drugs to a central pharmacy where pharmacists dispense medication according to a medical order outlined in the clinical protocol or pharmacist manual. With us, patients receive clinical supplies in 3–6 days rather than 3–6 months through traditional practices.

Cost

Our dispensing service will decrease costs; the primary savings is through eliminating unnecessary clinical supplies planning, packaging, and labeling. For most, cost estimates can be derived by directly comparing traditional packaging and labeling with our dispensing methods. Current pricing shows as much as a 50% savings. Ask for a quote and see for yourself.

Quality

RxE2 dispensing greatly improves the quality of clinical supplies dispensed to patients. Foremost, the pharmacist, the medication expert, counsels the patient according to state laws ensuring that the correct drug was delivered to the right patient and that the patient understands medication use and storage. Secondly, rather than the typical GMP-style label, RxE2 dispensing labels clinical supplies with a patient-specific pharmacy label providing the necessary information for proper use.